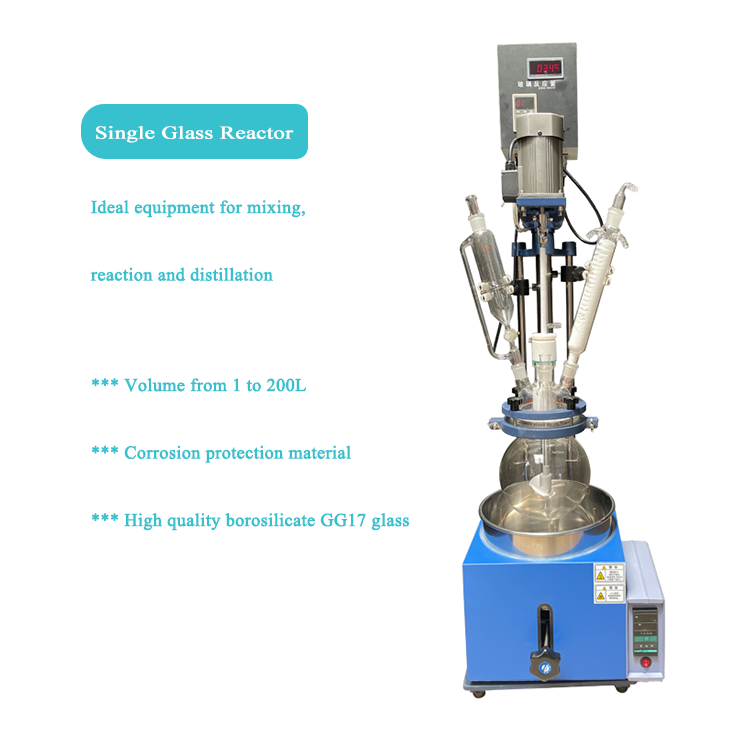

1L 2L 3L 5L Lab Chemical Bench Top Single Layer Glass Reactor is a single-layer glass design, and the reaction solvent is placed in it for stirring reaction, and hot water or hot oil is used for heating reaction. When cooling is required, a cooling coil can be added to the oil bath for cooling reaction. Under the set constant temperature, in a closed glass reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the requirements of use, and the reaction solvent can be refluxed and distilled. It is a modern fine chemical factory, biopharmaceutical and Ideal pilot and production equipment for the synthesis of new materials.

1L 2L 3L 5L Lab Chemical Bench Top Glass Reactor is a single-layer glass design, and the reaction solvent is placed in it for stirring reaction, and hot water or hot oil is used for heating reaction. When cooling is required, a cooling coil can be added to the oil bath for cooling reaction. Under the set constant temperature, in a closed glass reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the requirements of use, and the reaction solvent can be refluxed and distilled. It is a modern fine chemical factory, biopharmaceutical and Ideal pilot and production equipment for the synthesis of new materials.

This model glass reactor have many advantages:

1. Distillation and reflux can be carried out simultaneously;

2. High quality GG-17 high borosilicate glass have nice corrosion resistance;

3. Mixing speed and heating temperature digital display;

4. Passing on hot oil can do heating reaction, passing on freezing liquid can carry out low temperature reaction;

5. Convenient bottom discharge valve;

6. Muti-model, Mutil-volume optional.

7. Explosion-proof controller and motor for optional.

The structure of glass reactor: