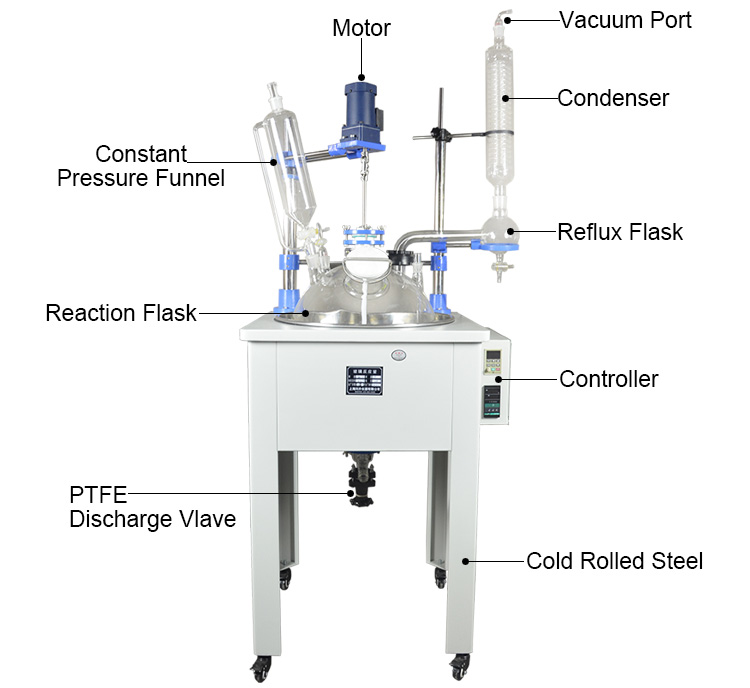

Lab research industry chemical hydrolysis single layer glass reactor can perform various solvent synthesis reactions under constant temperature conditions.The reaction part of the instrument is a fully controllable structure that can continuously suck various liquids and gases by using negative pressure. Do reflux or distillation at temperature.

Lab research industry chemical hydrolysis single layer glass reactor

Lab research industry chemical hydrolysis single layer glass reactor can perform various solvent synthesis reactions under constant temperature conditions.The reaction part of the instrument is a fully controllable structure that can continuously suck various liquids and gases by using negative pressure. Do reflux or distillation at temperature.

Its main characteristics are as below:

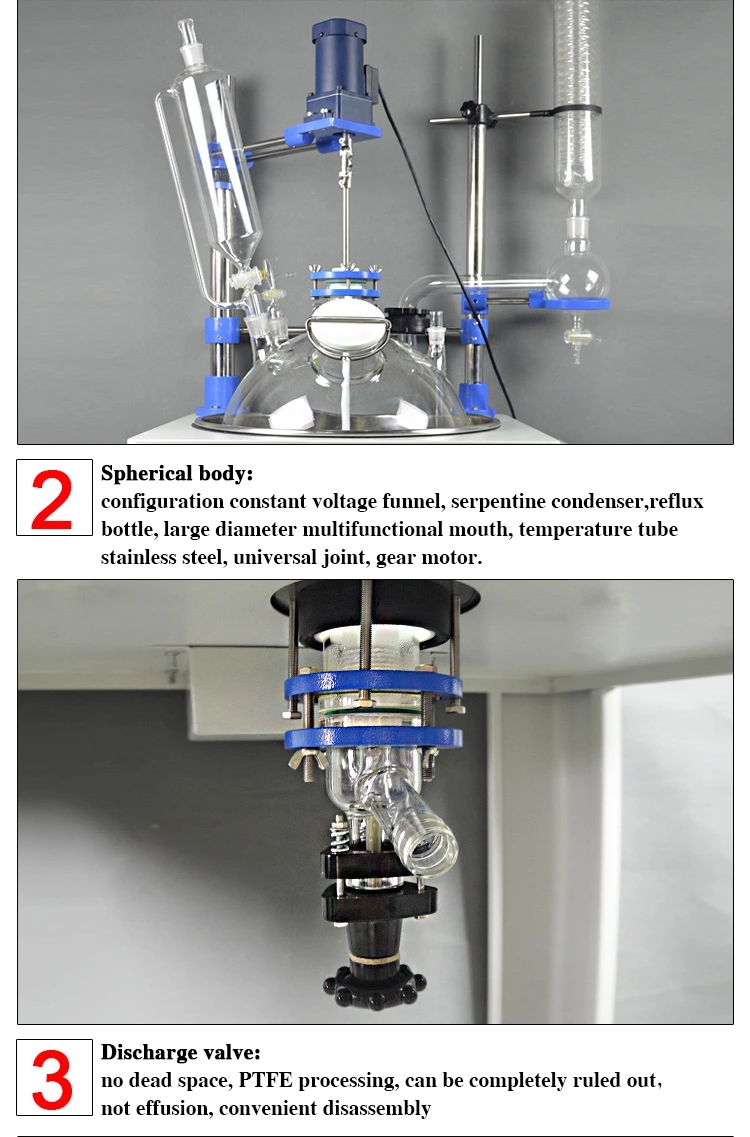

1.Distillation and reflux can be realized at same time;

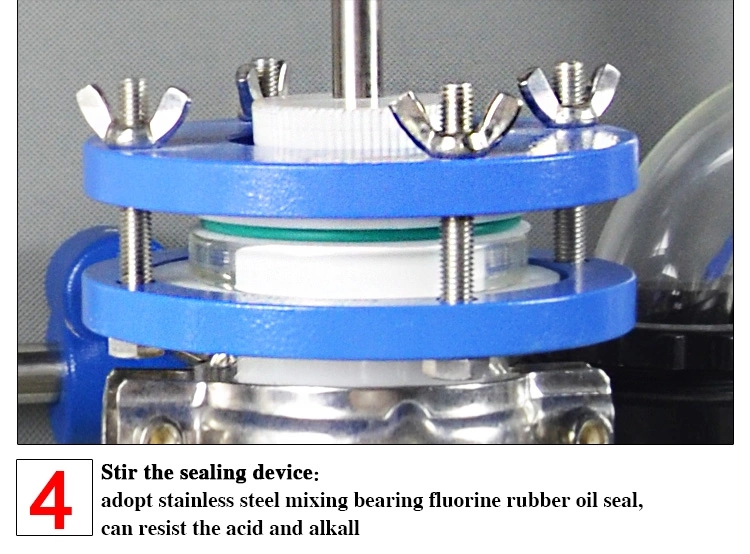

2.Continuous stirring and sealing effect is good; glass filter reactor

3.Stirred materials be put into GG17 glass bottle with PTFE sealing,there are no cross-contamination;

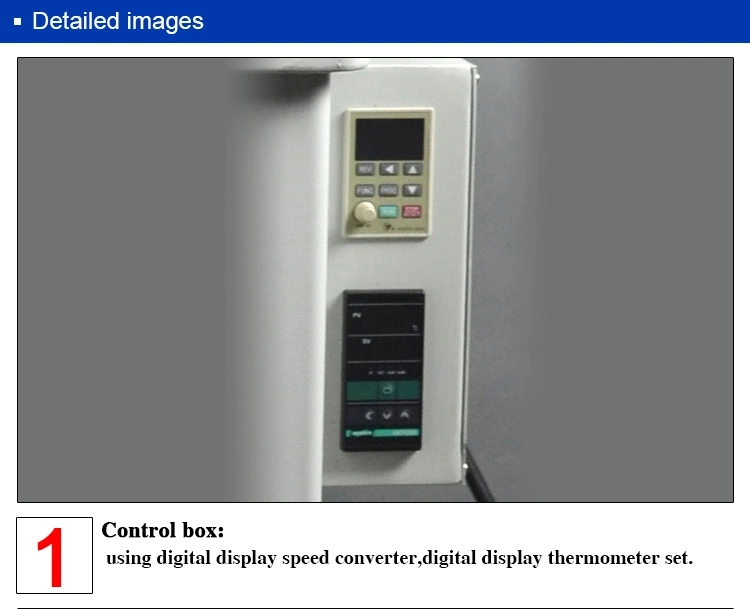

4.Digital display speed and low temperature display, easy to operate;

5.Large cleaning mouth, easy to make cleaning;borosilicate laboratory glass reactor.

6.Large discharge valve can discharge solid and liquid; glass chemical reactor

7. Intelligent microcomputer control, convenient operation and reliable performance.

The details of single layer glass reactor:

If volume, materials, motors and controllers have special requirements, we can also provide customized services. Please tell us your detailed requirements and we will give you a satisfactory solution.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

FAQ:

1. What is the purpose of the single-layer glass reactor?

It is an ideal pilot and production equipment for modern fine chemical plants, biopharmaceuticals and new material synthesis.

2. What are the disadvantages of single-layer glass reactors?

Can not do low-temperature reaction, uneven heating, it is not easy to visually observe the material reaction.

3. Why should a single-layer glass reactor be matched with a circulating water vacuum pump?

Provide negative pressure for the single-layer kettle and provide a vacuum state for material reaction.

4. What are the heating methods for single-layer glass reactors?

There are three heating methods for the single-layer kettle: water bath, oil bath, and electric heating mantle, which are equipped according to customer requirements. The temperature control method is intelligent digital display temperature control, with high temperature control accuracy.