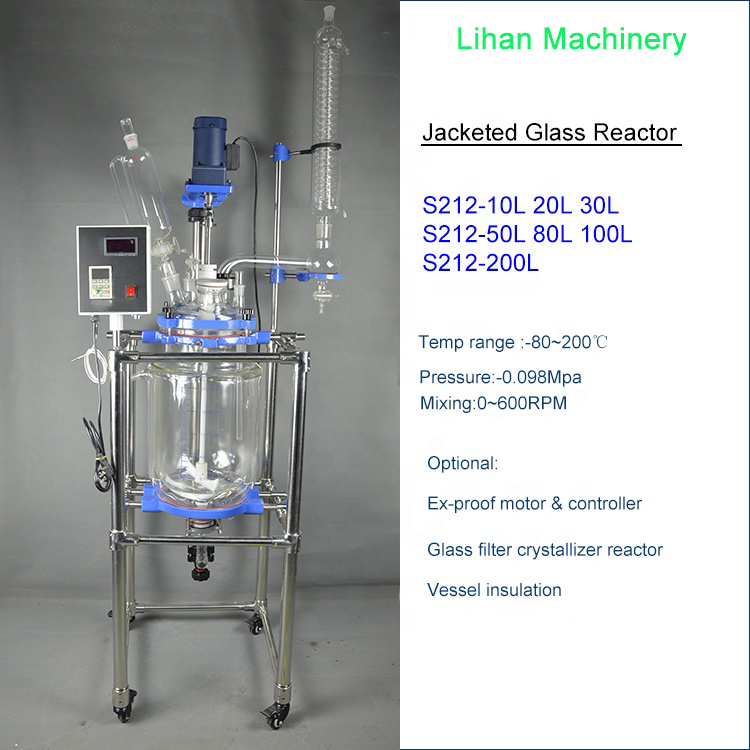

Jacketed glass reactor can mix, reaction and distillation. Its volume can be available from 1L to 200L. The jacket can be injected with water or oil medium, through the temperature control equipment for heating or cooling, so as to provide the corresponding temperature conditions for the reaction solvent. If you have customized requirements, such as explosion- proof motor, explosion-proof frequency converter, customized stirring rod, digital communication and so on, please don‘t hesitate to tell us, we can provide a best solution.

Chemical laboratory industrial double layer jacketed glass reactor

Jacketed glass reactor can mix, reaction and distillation. Its volume can be available from 1L to 200L. The jacket can be injected with water or oil medium, through the temperature control equipment for heating or cooling, so as to provide the corresponding temperature conditions for the reaction solvent. If you have customized requirements, such as explosion- proof motor, explosion-proof frequency converter, customized stirring rod, digital communication and so on, please don't hesitate to tell us, we can provide a best solution.

The Structure of jacketed glass reactor:

FAQ:

1.What is the working principle of the double glass reactor?

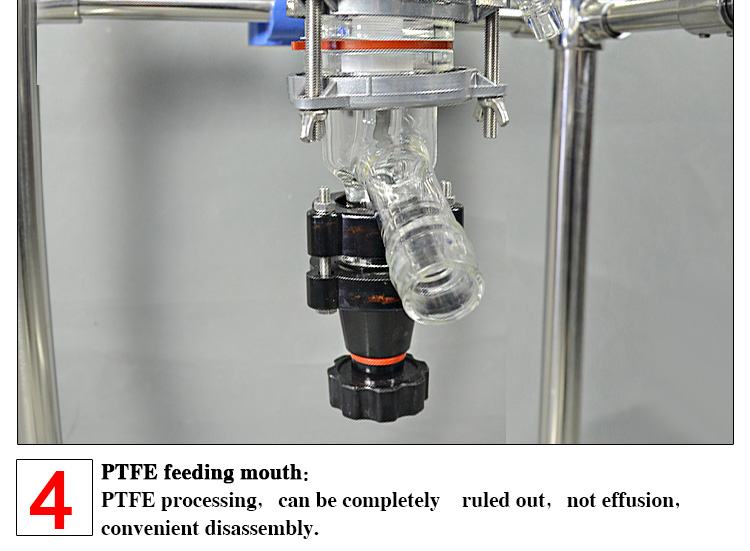

The glass reactor is sandwiched by the double-layer reactor, and a constant temperature (high or low temperature) hot melt or cooling medium is injected to heat or cool the materials in the reactor at a constant temperature, and the double-layer glass reactor can provide stirring. The materials are reacted in the reaction kettle, and the evaporation and reflux of the reaction solution can be controlled. After the reaction is completed, the materials can be discharged from the discharge port at the bottom of the kettle, and the operation is extremely convenient.

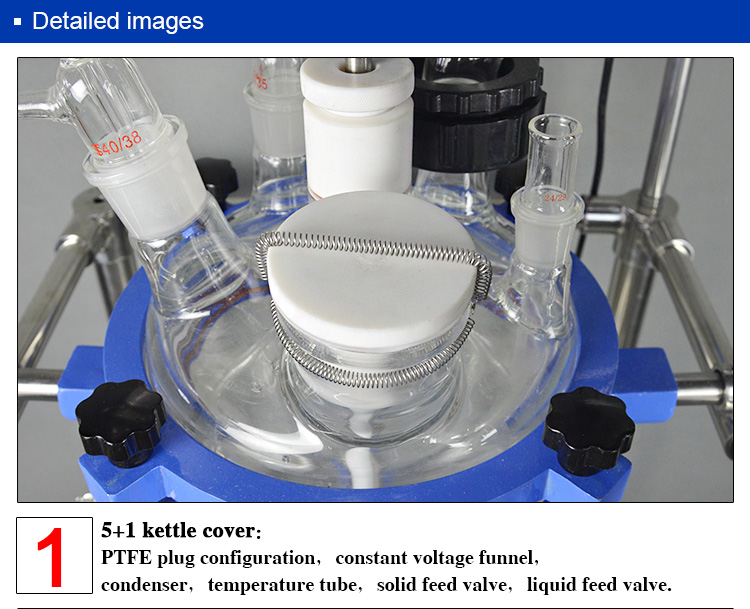

2. What are the accessories for the glass part of the double-layer glass reactor?

Double-layer kettle body, kettle cover, constant pressure dropping funnel, distillation elbow, serpentine condenser, thermometer sleeve, inlet and outlet valve, lower discharge valve, suction elbow, hollow plug.

3. What is the supporting equipment for the low-temperature reaction of the double-layer glass reactor?

High and low temperature integrated machine: It has both heating and cooling functions, and provides heating and cooling sources for the double-layer kettle in a circular manner, and intelligent temperature control

Low-temperature coolant circulating pump: refrigeration equipment, in a circulating manner, provides low-temperature cooling circulating water for the condensation system of the double-layer kettle, and the condensation medium is ethanol

4. What materials are used for the components of the double-layer glass reactor?

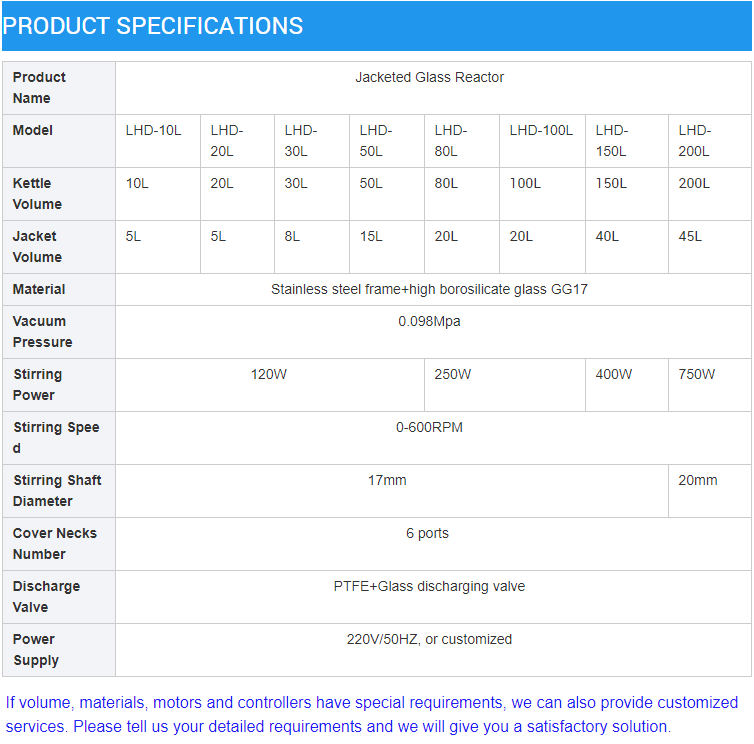

The use of high borosilicate glass has good chemical properties, is resistant to strong acids and alkalis, and can withstand a wide temperature range.