The crystallization reactor is a commonly used glass reactor for biochemical refinement, which combines the functions of the reactor and the filter. The crystallization reactor can make crystallization concentration, distillation, reflux. The Jacketed glass reactor part can be used for vacuum stirring reaction, high temperature and low-temperature reaction, constant speed operation mixing reaction, distillation, reflux, concentration reaction, negative pressure operation, and so on. While the filtration system can help in solvent recovery and filtration to improve the reactor‘s efficiency.

The crystallization reactor is a commonly used glass reactor for biochemical refinement, which combines the functions of the reactor and the filter. The crystallization reactor can make crystallization concentration, distillation, reflux. The Jacketed glass reactor part can be used for vacuum stirring reaction, high temperature and low-temperature reaction, constant speed operation mixing reaction, distillation, reflux, concentration reaction, negative pressure operation, and so on. While the filtration system can help in solvent recovery and filtration to improve the reactor's efficiency.

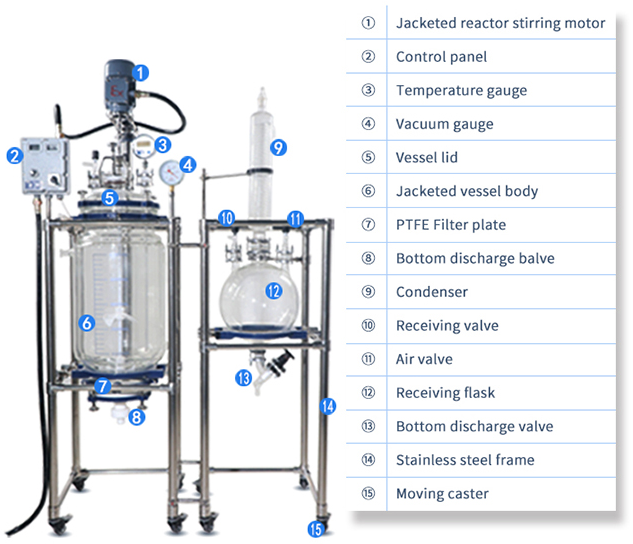

The structure of chemical filter glass crystallization reactor

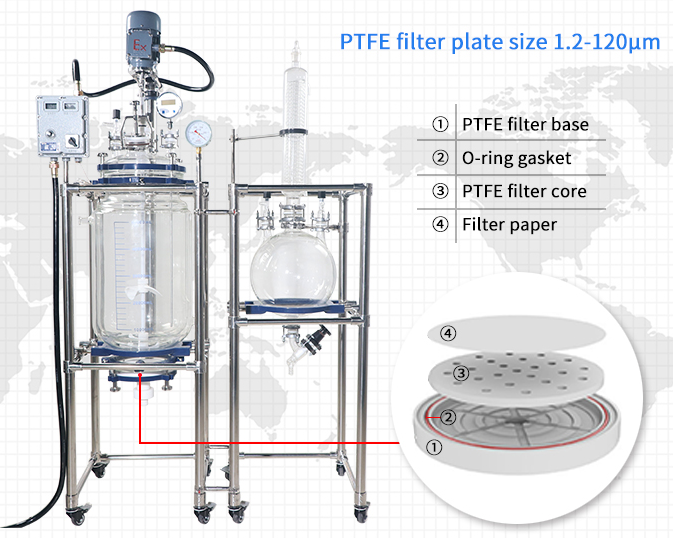

Multi-layer PTFE filter system provide excellent separation performance

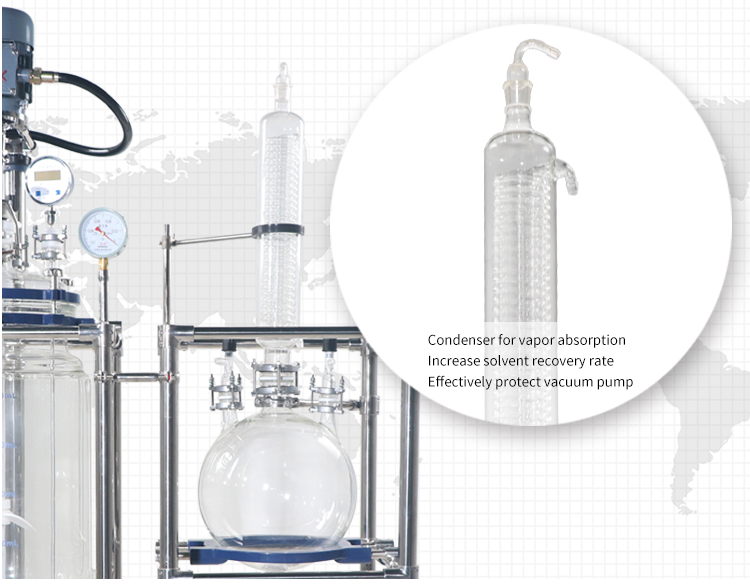

High efficient condenser with large condensation area, provide fast cooling performance to support fast solvent recovery.

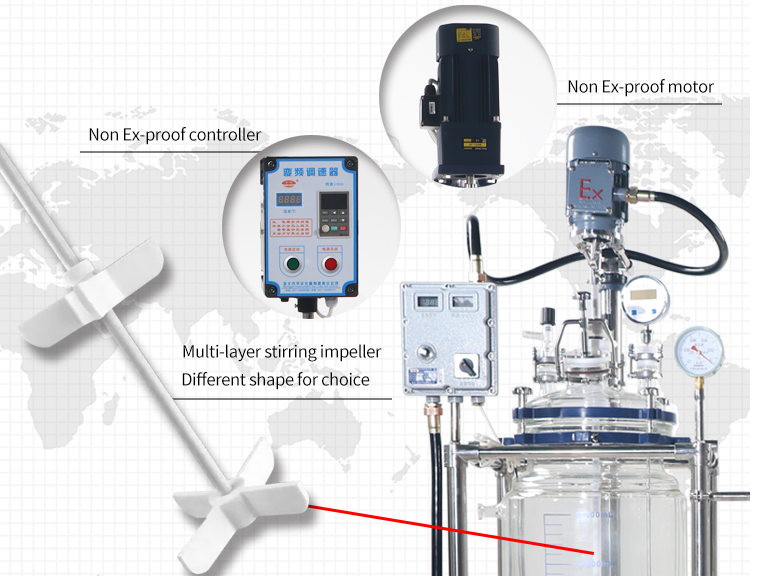

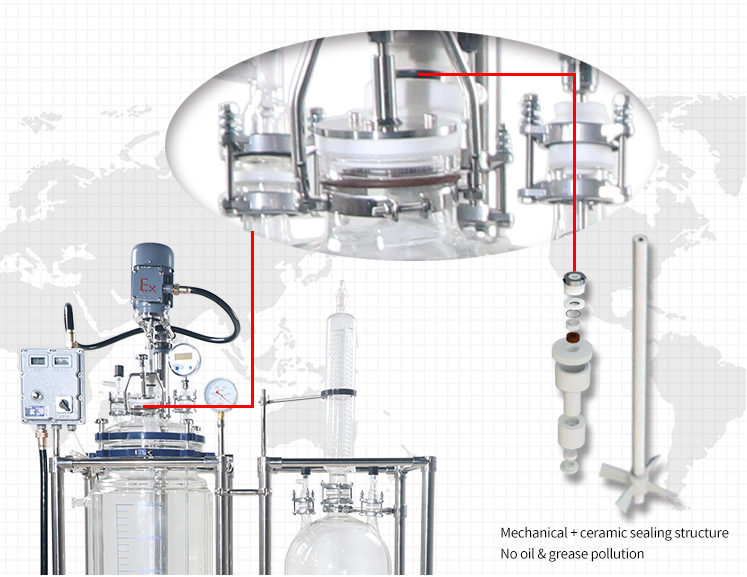

Powerful stirring motor provide continuous and stable stirring, you can choose common motor and explosion system.

Mechanical stirring seal and ceramic bearing stirring design, not only have good sealing performance, but also no oil pollution.

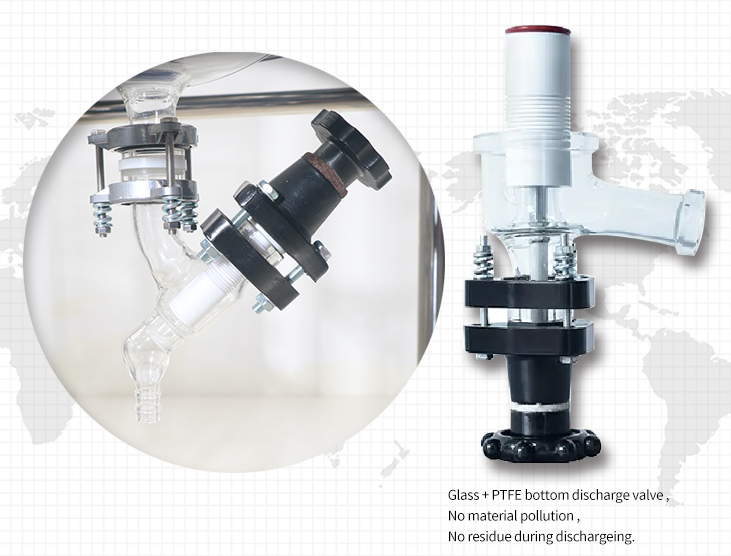

Upgrade alumimum flange+PTFE valve, provide prefect sealing effect.

The receiving flask with a bottom PTFE discharge valve, which has a zear dead space can guarantee the discharge is smoothly and no residue.

Auxiliary equipment